FL-300 boiling granulating drier

Use & Features

The method of boiling and granulating is a comprehensive fruit of spraying and fluidizing technology. It makes traditional mixing ,granulating and drying processes finish in the same closed container. So it is called as "one step granulator".

This machine has simple structure and is easy to clean and maintain .Not only it can make granule but also dry quickly. The process of mixing ,granulating ,drying will be finished in the same closed container at the same time. So it can prevent from pollution caused by contacting with environment and guarantee that the quality of medical granule is conformity with the requirement of "GMP".

The parts contacted with raw material are made of 316L stainless steel. The heating of machine can be divided into electricity or steam and the control part can be divided into ordinary form or computer form .Customer can choose it freely.

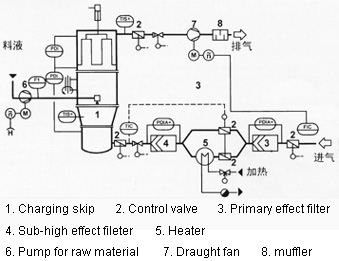

Schmatic of installation

Features

- Improve its fluidity and reduce powder dust to fly through powder granulating.

- Improve its solving property through powder granulating

- Mixing, granulating and drying can be finished in the same machine, i.e .one step to granulate.

- Being adapted anti-static electricity filtering cloth, the operation of equipment is safe.

- Being set discharge hole of pressure, if explosion were taken place, the equipment and personal can not be damaged.

- Automatic operation, or hand operation.

- There is a bleed hole, once explosion, this machine can't be damaged.

- Guard against electrostatic generation, adopt the cloth bag without electrostatic.

- The equipment has no dead corner. The loading and unloading is quick and convenient. It can be washed Clean. It is in conformity with the normal of GMP.

Scope of application

- Medicine granulating Granulating ; granulator of tablet, quick solved drink, granule used for capsule.

- Foodstuff granulating and coating: Sugar, coffee ,cocoa ,powder, cream ,powder syrup, amino acid, favoring, puffed food.

- Granulating for pesiticide ,pigment , dyertuff.

- Drying for powder ,granule, block raw materials.

- Coating: granulate, pill protection layer ,formulated color ,slow release ,film ,coating for intesting solving.

Technical Parameters

- Main machine is made of 316L stainless steel, 3 mm in thickness, inside surface adopts mirror polish, no dead corner, cleaning is very easy; outside surface adopts matte finishing.

- Hopper capacity: 1000 liters

Two charging wagons are equipped, material: 316L

- A charging wagon for raw material with liquid is equipped, 100 liters, Material: 316 L

- Production capacity for main machine: 250 - 300 kg/batch; 1000 - 1200 kg/8 hours

- Granulating time: 60 - 90 minutes/batch, 4 batchs/8 hours

- Working temperature: 50 - 150º Celsius

- Heating type: steam heating, steam magnetic valve control, SUS304 stainless steel tube with 19 x 2 stainless steel fin

- Air consumption: 1.3 m3/min

- Centrifugal fan with Explosion-Proof Motor : 37 KW, 1 unit

Noise snubber is equipped in the centrifugal fan.

- Frequency converter: 37 KW, 1unit

- Bag filter, 2 sets; vibrating cylinder, 2 sets; valve for air adjusting, 2 sets.

- Peristaltic pump, 1 unit, YT600-J

- Temperature meter : 3 units

- Spray gun, 1 pc; base of spray gun, 4 pcs; 3 fluid type, the height of spray gun can be adjusted.

- Ventilating system adopts primary effect, middle effect and sub-high effect filters, ensure hundreds of clean air.

Air filter box, 1 unit, with primary effect, middle effect and sub-high effect filters.

- Air drive fast valve at the air inlet, avoid the heat loss.

- Control cabinet, Material: 304# stainless steel, PLC control, touch screen operation.

- Main electrical components: SIEMENS

- Overall size: 5500mm x 2100 x 4100mm

Equipped Electrical Apparatus Components List

No. | Apparatus Name | Specification | Supplier | Qty |

1 | Upper cylindrical | 316L, 1600 mm in diameter 3 mm in thickness | Company | 1 |

2 | Middle cylindrical | 316L, 1600 mm in diameter 3 mm in thickness | 1 | |

3 | Charging wagon | 316 L | 2 | |

4 | Braket | SUS 304 # | Company | 2 |

5 | Hopper | 316 L, 3 mm in thickness | company | 2 |

6 | Charging wagon for raw Material and liquid | 316 L, 100 liters 3 mm in thickness | Company | 1 |

7 | Bag filter | Antistatic cloth | Company | 2 |

8 | Cooler | SUS 304 # , 150 mm2 | Company | 3 |

9 | Primary effect filter | SUS 304# | Company | 1 |

10 | Middle effect filter | 1200 x 1000 x 500 Non-woven fabrics | Company | 1 |

11 | High effect filter | 600 x 1000 x 350 | SUJING, Changzhou | 2 |

Frame of filter | SUS 304# | Company | 1 | |

13 | Air shutter | SUS 304# 360 | Company | 2 |

14 | Cylinder | QGB160 x 100-MF2 | Hualong, Wuxi | 2 |

15 | Cylinder | QGB80 x 1250-MF1 | Hualong, Wuxi | 2 |

16 | Cylinder | QGB63 x 200-MF4 | Hualong, Wuxi | 3 |

17 | Draught fan | 37 KW, Explosion-proof motor | Sufeng, Wuxi | 1 |

18 | Frequency converter | 37 KW | Dr. Lishile | 1 |

19 | Pipeline | SUS 304#, 1.5 mm in thickness | Company | 1 |

20 | Flange | SUS 304#, 14 mm, 16 mm and 20 mm in diameter | Company | 1 |

21 | Chimney | A3, 1.5 mm in thickness | Company | 1 |

22 | Silencer | A3, 1.5 mm in thickness | Company | 1 |

23 | Bolt | SUS 304# | Company | 1 |

24 | DN25 filter | Copper | Jiangyin, Jiangsu | 1 |

25 | Steam magnet valve | Wuxi,Jiangsu | 1 | |

26 | Control cabinet | PLC, touch screen, SIEMENS | Company | 1 |

27 | Pressure regulating valve | R3000 | AIRTAC | 4 |

28 | Separator of filtration of water | F3000 | AIRTAC | 2 |

29 | Lubricator | L3000 | AIRTAC | 2 |

30 | Integrated package Magnet valve | AC24V | AIRTAC | 1 |

31 | Pneumatic magnet valve | 6 pcs, 1 double control ; 5 single control | AIRTAC | 7 |

32 | Hot resistance | Pt100 | Shanghai | 2 |

Remark: The final components are subject to the function and requirement of your needed machine.