JP-300D Automatic paper plastic blister packing machine

Descriptions

JP-500D automatic blister packing machine adopts frequency control of motor speed. Collecting machine, electricity, photo, air to integrate, and innovative design, Manufacture according to national standard strictly, flexible stroke, modularize station structure, easy operation, high output, low noise, and equipped with Beautiful out looking, this is the ideal packing machine.

JP-500D main devices include PVC heating, blister forming, blister detection (Optional), products feeding, products lack detection (optional), stroke pulling, Punching, transporting, heating and sealing and so on.

The PVC formed after heating and being soften in the forming mould. The blister fed Product via blister detection device then into the punching device to make the single Blister with product. After then, the blister delivered to heating and sealing device. At last, the finished products sent out next procedure.

All the devices work synchronously. The blister forming and products deeding equipped with the sensor in case of the bad blister and lack of products in blisters. Waste products rejected out via waste products exit.

This machine is suitable for blister card packaging for such industries as food, Medicine, medical equipment, toys, hardware, small appliances, electronic, Automobile and motorcycle, daily necessities, cosmetics, rubber products,

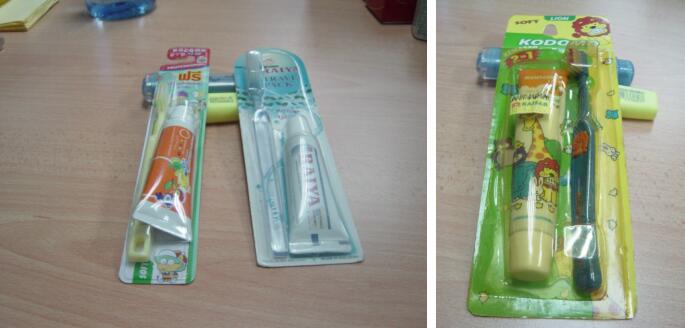

Tableware, kitchenware, sports and other related industry. Such as injections, Toy guns, burning torch, toy cars, scissors, alarms, batteries, pens, solid glue, tooth Brushes, lipsticks, coat & has hooks, chopsticks, cleaning balls, bottle openers and So on.

Working process:

PVC unrolling PVC heating PVC tray forming Servo drawing PVC tray Punching and cutting PVC waster rolling PVC tray turning and locating Product feeding automatic paper feeding heating sealing final product Output.

Features

- Mechanical transmission, servo motor drawing, reasonable structure, easy Operation.

- 304# stainless steel cover, beautiful outlook, convenient to clean.

- PLC control system, frequency speed control, this will reduce the noise and Make the machine to run stably.

- Photoelectrical control, automatic detection, this will improve the safety Performance.

- Integral card feeder to reduce labor force.

- The whole machine can be separated, which is convenient for lift delivery.

- Design the mould and automatic feeding method according to different Product shape.

Technical Parameters

Maximum punching speed | 13 - 25 times/min |

Maximum package size | 300x180x40 mm (PVC blister) 300x200 mm (Paper card) |

Adjustable travel scope | 40 - 180 mm |

Applied packing materials | Paper card and plastic |

Packaging materials | (0.15 x 0.5) x 300 mm |

Total power | 10.5 KW |

Power supply | AC, 380V/50HZ 3 phase |

Air consumption | ≥ 0.5 M3/min(self-prepared) |

Air pressure | 0.5 - 0.8 MPa |

Overall size | 2960(L)x 2040(W)x 1900(H)mm |

Net weight | 1500 kg |

Automatic paper plastic blister packing machine JP-300D

No. | Product | Type and Sepc | QT | Origin or brand |

1 | Servo Motor | MHMD082P1U MCDDT3520 | 2 sets | Panasonic |

2 | Reducer | 90-WPE-010 90-PLE-010 | 1 pc | Pamasonic |

3 | Touch Screen | 6AV6648-OBC11-3AXO | 1 pc | Siemens |

4 | Encoder | E6B2-CWZ6C 1000 wire | 1 pc | Omron |

5 | Invertor | 3G3JXZ-A4015 | 1 pc | Omron |

6 | PLC | 216-2AD23-OXB8 | 1 pc | Siemens |

7 | PLC extend | 222-1BF22-OXA8 | 2 pcs | Siemens |

8 | Temperature module | 231-7PD22-OXA8 | 1 pc | Siemens |

9 | Power switch | NES-100-24 | 1 pc | MengWei Taiwan |

10 | Photoelectric switch | E3Z-T61A 2M | 6 pcs | Omron |

11 | Auxiliary Repay | LY2NJ DC24V | 4 pcs | Omron |

12 | Auxiliary Repay | S40194N-D24 | 2 pcs | KeXiang |

13 | Proximity Switch | TL-Q5MC1-2 | 5 pcs | Omron |

14 | Solide-state Relay | SSR-40DA | 3 pcs | MengWei Taiwan |

15 | Air Switch | SMART 3P/C10 | 1 pc | Schneider |

16 | Air Switch | SMART 3P/C40 | 1 pc | Schneider |

17 | Air Switch | SMART 2P/C10 | 2 pcs | Schneider |

18 | Air Switch | SMART 1P/C20 | 3 pcs | Schneider |

19 | Air Switch | SMART 1P/C6 | 1 pc | Schneider |

20 | Button | ZB2BA | 3 pcs | Schneider |

21 | Button | ZB2BG | 1 pc | Schneider |