DCS-1C-1 Automatic weighing & packing machine

Descriptions

This unit is manual work aid filling, automatic weighing, pneumatic element to seal packaging, automatic filling, and automatic sealing by conveyer. By changing the method of feeding material, fits for the fluid granular such as milk powder, rice, bean, fodder, white sugar, or any thing low fluidity, such as flour, milk powder, pesticide, dyestuff.

Features

- Double screw feeder or arc double-speed feeder system: simple structure, stable precision.

- The central of control and weighing consist of Mitsubishi PLC, Mettler Toledo weighing sensor and weighing terminal. Maximize accuracy of weighing and stability.

- English display, show parameters and working conditions, easy to control.

- Complete machine which contact with material made of stainless steel, adapt to amyctic materials.

- Changeable pneumatic grip, good leak tightness, fits for all size of package.

- Chemical industry belt, plastic chain belt, to select.

- Industry seam machine, plastic sealing machine optional.

Technical Parameters

Metering Mode | Weighing (Gross weight form) |

Feeding Mode | 5-50Kg |

Packaging Weight | ≤±0.2% |

Packaging Rate | ≥3 bags/min |

Power Supply | 3P / 220V 50-60Hz |

Total Power | 2.25 KW |

Air Supply | 6kg/cm2 0.2m3/min |

Total Weight | 600Kg |

Overall Dimensions | 4000(variable depending on the conveyor)x1350x2500mm |

Optional device:

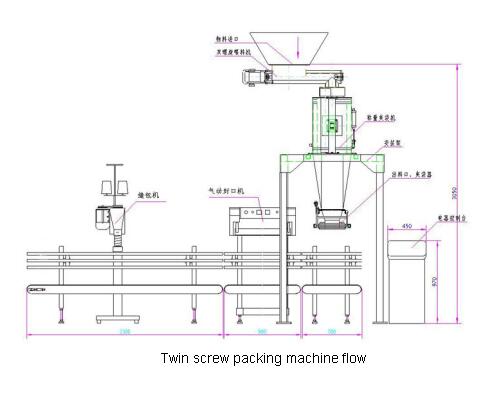

DCS-1C-2 Automatic weighing & packing machine

Descriptions

This unit is manual work aid filling, automatic weighing, pneumatic element to seal packaging, automatic filling, and automatic sealing by conveyer. By changing the method of feeding material, fits for the fluid granular such as milk powder, rice, bean, fodder, white sugar, or any thing low fluidity, such as flour, milk powder, pesticide, dyestuff.

Features

- Double screw feeder or arc double-speed feeder system: simple structure, stable precision.

- The central of control and weighing consist of Mitsubishi PLC, Mettler Toledo weighing sensor and weighing terminal. Maximize accuracy of weighing and stability.

- English display, show parameters and working conditions, easy to control.

- Complete machine which contact with material made of stainless steel, adapt to amyctic materials.

- Changeable pneumatic grip, good leak tightness, fits for all size of package.

- Chemical industry belt, plastic chain belt, to select.

- Industry seam machine, plastic sealing machine optional.

Technical Parameters

Metering Mode | Weighing (Net weight form) |

Feeding Mode | 5-50Kg |

Packaging Weight | ≤±0.2% |

Packaging Rate | ≥6 bags/min |

Power Supply | 3P / 208 - 415V 50/60Hz |

Total Power | 2.5 KW |

Air Supply | 6kg/cm2 0.3m3/min |

Total Weight | 800Kg |

Overall Dimensions | 3700x1600x3100mm |

Optional device: