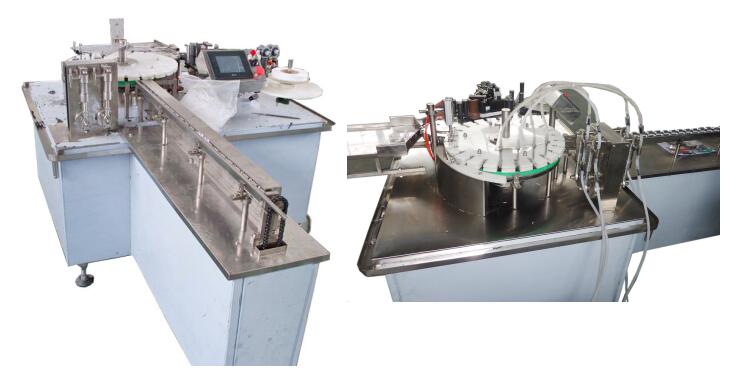

Nonstandard liquid production line of filling, capping and labeling

Descriptions

This machine can complete liquid filling, capping and labeling for plastic bottles automatically.

This machine supplies the bottles by manual, and filling, capping and labeling by PLC control, frequency conversion adjusting speed, so the operation is simple and steady.

This machine is applied to liquid filling in the foodstuff, pharmacy, chemical and cosmetic etc industries.

Features

- PLC control system, frequency conversion adjusting speed.

- Touch screen operation, easy operation.

- Equipped 4 filling nozzles, the maximum capacity is 4000 bottles/min.

- No filling, no capping and no labeling when no bottle.

- Code printer is equipped, which can print the batch number etc.

- The whole machine is made of high quality stainless steel, meet the GMP standard.

Technical Parameters

Applied bottle | Plastic bottle |

Production capacity | 3000 - 4000 bottles/hour |

Filling rate | ≥ 99% |

Capping rate | ≥ 99% |

Labeling rate | ≥ 99% |

Power | 5 KW |

Power supply | AC, 380V/50HZ 3 phase or customization |

Noise | 50 dB |

Overall size | 3200x900x1600 mm |

Major components:

Designation | Specification | origin | Remark |

Main parts | customization | Company | Stainless steel, nylon |

Main control system | ZhengTai company | ||

Measuring pump | customization | Company | Stainless steel |

Perfusion tube | 6 mm | Shanghai | Silica gel |

Motor slowdown | 100YYJT120 | Wei Te, Beijing | |

Uniform scale | 24 parts | Company | Nylon 1010 |

Capping system | Company | ||

Retarder | WPA60 | Shanghai | |

Motor | 380V,1.5 KW | Shanghai | |

Transducer | VFD015S21D | TaiTA, Taiwan | |

Touch-screen | D0P-AS57BSTD | TaiTA, Taiwan | |

PLC | DVP24SS11T2 | TaiTA, Taiwan | |

Labeling motor | 90YYJT90 | Wei Te, Beijing | |

Step motor | ST86HS156A | Shanghai | |

Step driver | ST4HBXA | Shanghai | |

Code printer | HP425-B | Xiamen | |

Small motor | 90YYJT90 | Wei Te, Beijing | |

Phototube of bottle | BF3RX | Company | |

Phototube of label | BF3RX | Company |