RJWJ-250 Soft capsule production line

Descriptions

This machine is the absorption of advanced technologies at home and abroad, based on a combination of soft capsule production process and the characteristics of the use advanced technology and high quality materials. Meet the GMP requirements of well-designed.

This machine consist of soft capsule machine, sol pot, mould (die roller), capsule conveyor, tumbler dryer, cooling air machine, vacuum pump, drying tray, vacuum mixing barrel and electrical control system and other ancillary equipment.

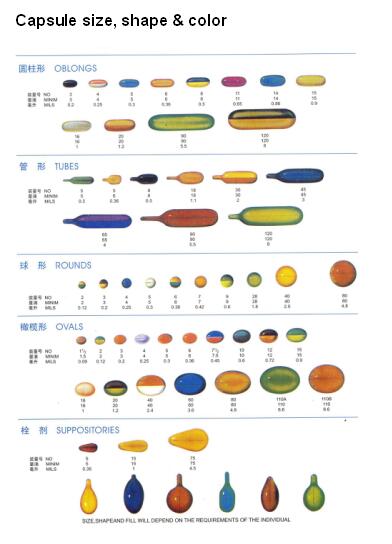

This machine cans all kinds of drugs, food, cosmetics, oils and hydrophobic substances in the quantitative suspension or paste injection pressure and encapsulated in gelatin membrane, the formation of various sizes in sealing the soft capsules.

This machine is widely used in health products, pharmacy and foodstuff etc industries.

Features

- Mould and mould shaft was optimal design, to prevent the damage during the moulds installation.

- Special use wedge installation device.

- Each system independent control, coordinated accordingly, easy to adjust.

- Mould pressing type, pneumatic pressure pressing, digital display, easy to adjust.

- Low noise design, there is no noise increase when highest and lowest speed operation improved working conditions.

- Adopts non-oil or micro-oil lubrication, it is easy to evaporate the water of the capsule, shortened the drying time.

- For most of the soft capsules no need to clean by alcohol or ether. To prevent the hurt from the solvent to capsules( excepting the printed soft capsules)

- Precise gelatin film thickness adjustment independent film spreading control, it is flexible and suitable to various kinds of gelatin solution and moulds, reaches the max using rate of gelatin solution.

- Two sides gelatin film linear conveying, no need adjust, production stable.

- Mould adjustment: free opposite line design, simplified operation, to prevent operator's mistake.

- Wedge lifting type: electrical-driven and self-lock, safe and dependable.

- Material supply pump: free adjust design, easy install, prevent operator's mistake, all rolling bearing design, prolonged using life.

- Gelatin film cooling type; auto-control water cooling, air blow balance, equipped with machine.

- Capsule fast shape fixing: special air blow device, reduce the temperature of capsule output part easy for the capsule shape fixing.

- Temperature control material hopper, Precise temperature control, auto liquid level control, it is suitable to various kinds of material requirements.

Technical Parameters

Mould (die roller) | ¢150 x 250(L) mm |

Mould pressure | 0.1-0.5 MPa |

Mould speed | 0-6 r/m |

Filling volume | 0-2 ml |

Production capacity | 75000 capsules/hour |

Filling precision | ± 1 % |

Machine power | 9 KW |

Power supply | AC, 380V/50HZ 3 phase or customization |

Net weight | 1400 kg |

Overall size | 2110 x 1000 x 2000 mm |