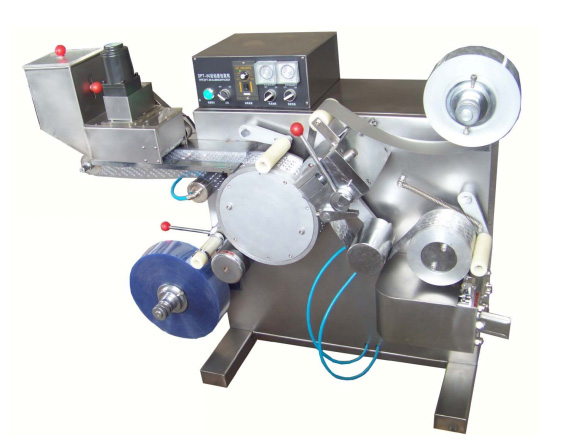

DPT-80 Mini Alu / PVC Blister Packing Machine

Use & Features

Designed by our company earliest and produced at largest batch process, DPT-80 mini-type Bubble-cap packing machine is the smallest, lightest, cheapest and energy consumption Lowest packing equipment among the similar mode both in domestic and abroad.

This machine is widely suitable for new product preparation room of pharmaceutical section Of people's hospital, small pharmaceutical factory, drug rest. It's also suitable for aluminum Sculpture packing of capsule, sugarcoating tablet and plain tablet medicine or improvement packing of special specification.

This machine can continually and automatically complete the packing proceedings, is blister cap form-taking, medicine-feeding, heat sealing, printing lot no, and cutting into format. It Has advantage as compact structure, full function, gear wheel working, and accurate Synchronization, stable cooperation, easy to replace the mould, low cost and needn't to equip Auxiliary unit. Turn on power and connect it with cooling water, you can produce in a large scale.

Technical Parameters

Item/model | DPT-80 |

Capacity | 20,000-50,000 pcs/hour |

Punching frequency | 30 times/min/plate each punching |

Plate size | 90x80 mm(designed according to customers' requirement) |

Packing material | PVC hard piece: width: 65-90 mm, thickness: 0.25-0.30 mm Bore diameter of roll shaft: 60-70 mm PTP aluminum foil: width: 65-70 mm, thickness: 0.02-0.025 mm Bore diameter of roll shaft: 60-70 mm |

Power | 1.5 KW |

Power supply | AC, 220V/50-60 HZ, 1 phase |

Overall size | 980(L)x480(W)x980(H) mm |

Weight | 230 kg |