Rotary Tablet Press ZPTX420-17G specially for dishwasher tablet press

Performance

The machine is a double-pressing automatically revolving piece-pressing machine which could make grain be pressed to be round piece, be carved characters ,special shapes and double color piece prescription .It is mainly used in manufacturing piece prescription for pharmaceutical industry enterprises like chemical industry ,foods, electronics.

Main Features

1. The cover is made of stainless steel with close type. The inner tablet surface is also applied with stainless steel materials which could keep surface luster and prevent from being polluted crossly, comply with GMP requirement.

2. Equipped with organic transparent window which could help to observe the status of pressing piece. Side blank could be fully opened, easy to clean and maintain.

All monitors and operating components are in good order.

Applying with frequency changing, speed regulating apparatus to do electricity regulation. The convenient operation and smooth revolving are safe and correct.

It is equipped with over-load protection apparatus. When pressure overloads, the machine will stop automatically.

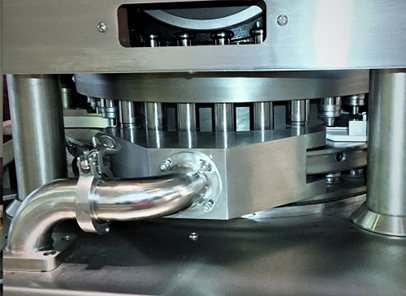

Machine Photo

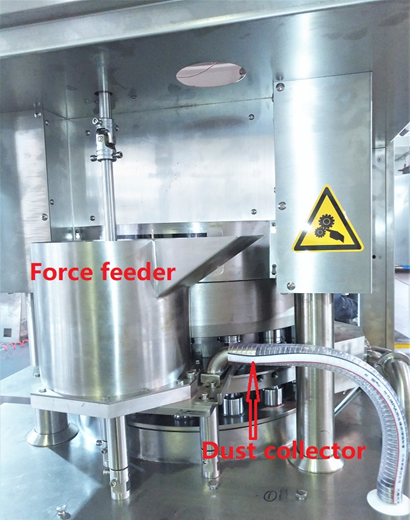

Modular designed dust collector nozzle covers large space of the middle die table and can absorb the residue powders effectively. The modular design can be removed and cleaned very easily.

Force feeder:

Force feeder can make sure the material can be impelled into the middle dies evenly and effectively, to make sure the filling speed and match the pressing speed and the tablets are of the same weight.

Model No. | ZPTX420-17G |

Punch Dies (stations) | 17G |

Max. Pressure (kn) | 120 |

Max. Tablet Diameter (mm) | 40 |

Filling Depth (mm) | 28 |

Max. Tablet Thickness (mm) | 7-14 |

Upper punch length(mm) | 175 |

Lower punch length(mm) | 192 |

Max rotation speed(r/min) | 20rpm for one color irregular shape |

Max Production speed (Pcs/h ) | 40800 pcs for one color irregular shape |

Max. rotation Speed (r/min) | 16rpm for 2 colors irregular shape |

Max. Production Capacity (pcs/h) | 16300pcs for 2 colors irregular shape |

Motor Power (kw) | 7.5kw/6grade |

Overall Size (mm) | 1100*1250*1870 |

Weight (kg) | 2000 |

Above speed is for reference, actual speed depends on the physical characteristics of the raw material.

Appliance Configuration List

Name | Type | Manufacturer |

Motor power | 7.5kw-6poles | Shanghai Dedong |

Transducer | P/N 132F0026 | Danfoss |

Cocontactor | 3TB4322-OX 220V | Siemens |

Contactor | 3TB4022-OX 220V | Siemens |

Relay | MK2P-1/AC220V | Omron |

Relay | MK2P-1/DC24V | Omron |

Thermorelay | JR36B-20 | Siemens |

Magnetic Ballast for Fluorescent Lamp | BPL9W220VB2SC | Phillips |

Little Triphase Breaker | 5SJ63 | Siemens |

Emergency Stop Button | AR22V2R-11R | Fuji |

Key Switch | AR22JR-3A11A | Fuji |

Indicator Light | DR22E3L-E4G | Fuji |

Travel Switch | LX19-001 | Shanghai Huatong |

Fan | FK3321.100 | Shanghai Leipu Electric |

Control Button | AR22PR-210B | Shanghai Huatong |

Register | In accordance with appliance eg:40:1×30 | Shanghai Handwheel Revolution |

Rattle Ware | DR22BS-220V | Fuji |

Switch | HGS-25-24 | Shanghai Hengji |

Screw Fuse Porcelain Base | RL1-15 | Shanghai Huatong |

Above data will be possibly upgraded or changed without notice, for exact data please contact us stf at stctp.com

Materials Configuration List

Name | Material | Outside heat treatment hardness |

Turret table | 1QT500-7 made of cast iron (standard configuration) 245# hard searing-iron on the surface( elective) 3SS30 stainless steel central disc( electiv) | / |

Materials of spigot shaft and transmission shaft | GB/T3077-1999 stated 40Cr medium carbon steel structural iron | / |

Turbine of main transmission | GB/T1176-1987 stated ZQSn10-1 tin bronze | Outside heat treatment hardness HRC45-48 |

Worm’s turbine | GB/T3077-1999stated 40Cr medium carbon steel structure | Outside heat treatment hardness HRC45-48 |

Clamping roller | GB/T1222-1984 stated GCr15 high carbon ferro-chrome | Heat treatment hardness in surface of excircle of clanying roller is HRC60-62 |

Guideway | GB/T1222-1984 stated GCr15high carbon ferro-chrome | Steel guideway and the place which drill drift touches the heat treatment hardness is HRC58-62。

|

Batch charger | Tin bronze ZQSn6-6-3, searing-iron on the surface | / |

Middle board | More than GB9439-1998 stated cast iron of HT200 | / |

Main material | More than GB9439-1998 stated cast iron of HT200 | / |

Chute | Stainless steel (OCr18Ni9) | / |

Faceplate mask | Stainless steel (OCr18Ni9) | / |

Clanying rollermask | Stainless steel (OCr18Ni9) | / |